LyoFlux® 200 TDLAS Water Vapor Mass Flow Monitor

Relevance & Measurement Concept Behind This Technology

Tunable Diode Laser Absorption Spectroscopy (TDLAS) is a Near-Infrared (NIR) spectroscopic measurement technique based on absorption of energy by gas molecules at a specific wavelength in the electromagnetic spectrum (“absorption line”). During transmission of a diode laser beam at the absorption wavelength through a sample containing the target gas, the beam intensity is reduced according to the Lambert-Beer relation. Using the measured transmission intensity, the number density of the target gas molecule in the sample gas is determined gas concentration measurement. The laser wavelength is rapidly tuned through a narrow spectral band and is capable of measuring multiple spectra (100) per second which are averaged to provide high signal to noise (SNR) data. The advantages of the TDLAS technology include the high detection sensitivity for the target molecule (water vapor), its measurement specificity, and the exact concentration measurements.

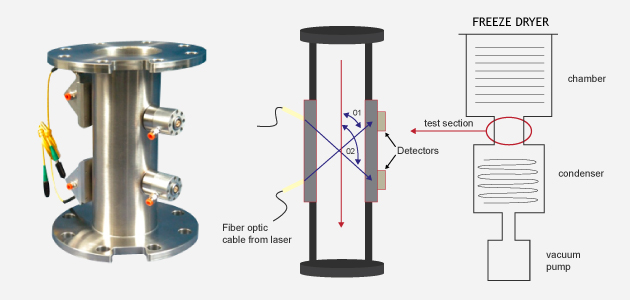

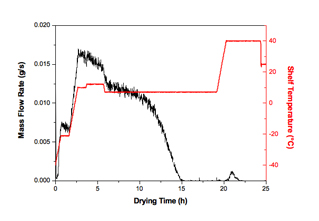

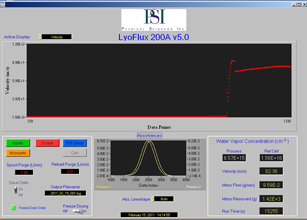

The use of LyoFlux® 200 (Physical Sciences Inc., Andover, MA, USA) in a freeze dryer is different from standard TDLAS gas concentration measurements. The LyoFlux® 200 determines the water vapor absorption lineshape in the spool of a freeze dryer by orientation of the diode laser beam at an angle to the gas flow axis (Figure 1). Using this measurement configuration the absorption feature is shifted in wavelength or frequency dependent upon the gas flow velocity. The measured spectrum is compared to either a static low pressure reference cell or to a second laser beam launched in the opposite direction with respect to the gas flow within the freeze dryer spool. Ultimately, a calculation of the gas flow velocity based on the Doppler shift between the two absorption peaks is possible. Gas flow velocity, in combination with the gas concentration and the spool cross-sectional area, allows an instantaneous determination of the mass flow rate, dm/dt, throughout the freeze drying process (Figure 2). In addition, a subsequent, software-based integration of dm/dt provides a continuous prediction of the total amount of water removed from the product (Figure 3).

Key Features

- Continuous, non-invasive monitoring of water vapor concentration, gas flow velocity and mass flow rate (dm/dt) during freeze-drying in all scales of freeze-drying equipment.

- Continuous mass balance determination.

- Highly sensitive endpoint determination for both primary and secondary drying.

- Real-time calculation of average product temperatures.

- Real-time calculation of average product resistance (Rp).

- Assessment of heat transfer coefficients for vials (Kv) or other container systems.

- Performance testing of freeze dryers.

Why Do We Use This Technology?

LyoFlux® 200 helps us to better understand the instantaneous changes in water vapor mass flow, and thus the sublimation rate for a given product during freeze-drying. This is of particular interest for products processed in atypical container systems (e.g. syringes, PCR-plates, etc.). In addition, mass flow measurements obtained from LyoFlux® 200 are sufficiently sensitive, even when using very small product loads in the freeze dryer. The technology further allows us a proper determination of heat transfer coefficients for primary packaging materials. Lastly, LyoFlux® 200 is one of the most helpful tools for performance testing of a freeze dryer.

Further Reading and Resources:

Short technical notes on TDLAS technology may be obtained in our Scientific Insights section. Recent research articles on TDLAS are highlighted in the GILYOS Scientific Library. For more product-related information, please visit the website of the manufacturer: Physical Sciences Inc.